| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Place of Origin : Henan, China

Shape : Powder

Material : Mullite

SiO2 Content (%) : 24-40

Al2O3 Content (%) : 60-75

MgO Content (%) : International standard

CaO Content (%) : International standard

Refractoriness (Degree) : 1770°< Refractoriness< 2000°

CrO Content (%) : International standard

SiC Content (%) : International standard

Model Number : 325, 200, 0-1, 1-3, 3-5, 5-8

Brand Name : Hongtai

Product name : fused mullite

Application : mullite brick

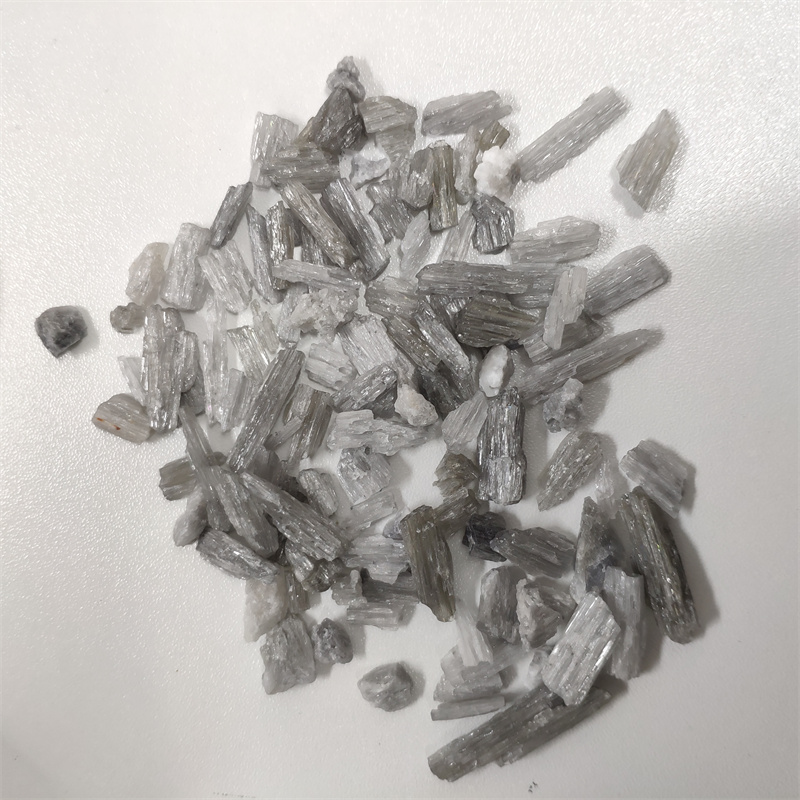

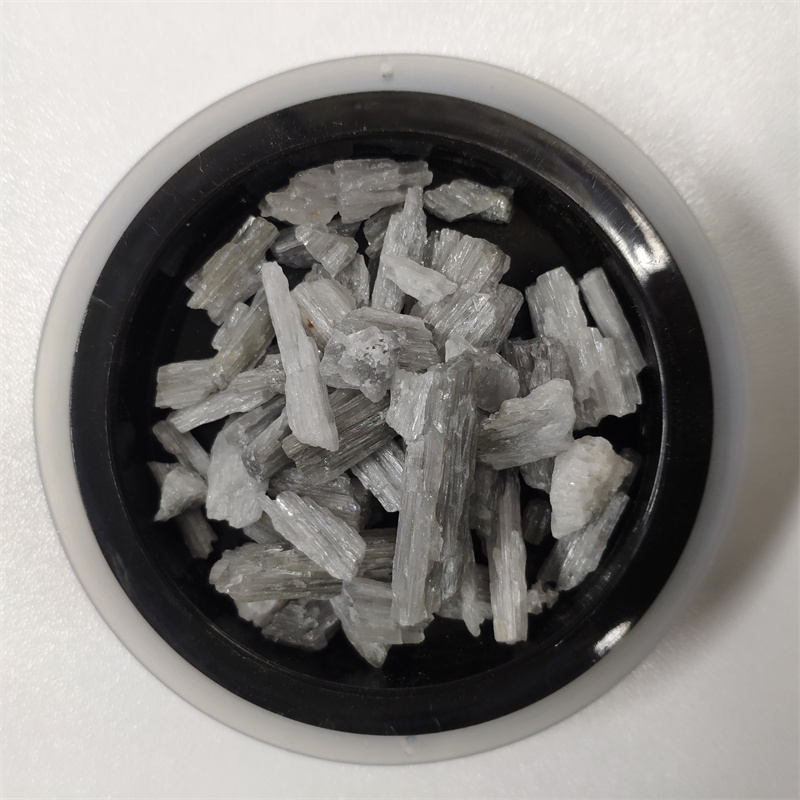

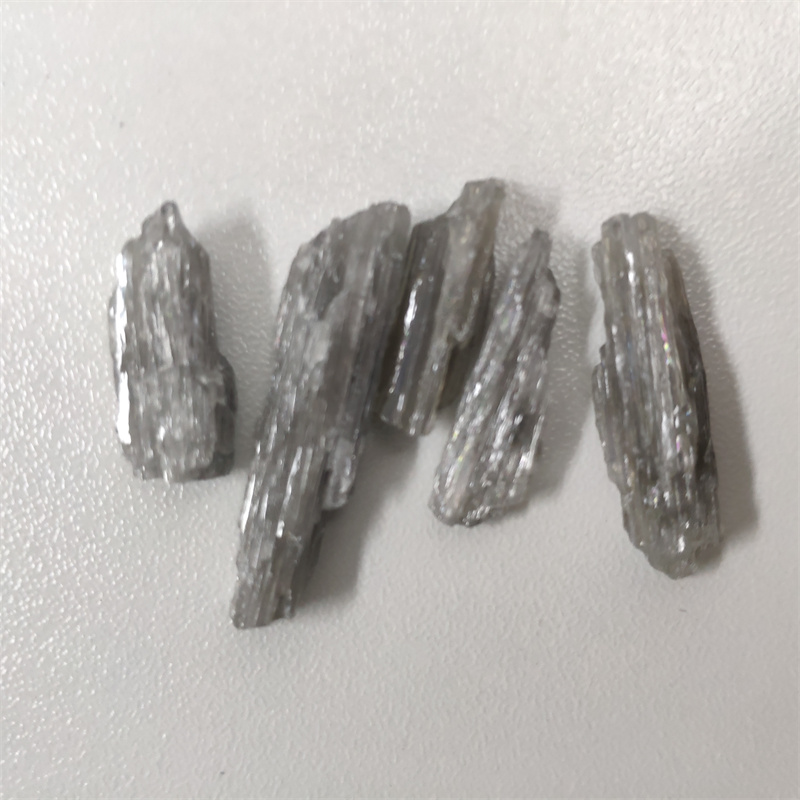

Color : white grey

Raw material : mullite

Usage : raw material of mullite castable and mullite brick

FE2O3 : 0.3-0.5

Na2O : max 0.8

Density : 2.7-2.8g/cm3

Package : 1 Ton /jumbo Bag

Keyword : fused mullite

Supply Ability : 6000 Ton/Tons per Month

MOQ : 650 tons

Price : $1,000.00/tons >=650 tons

Fused mullite is made by melting batch materials in an electric arc furnace and cooling and devitrifying mullite from the melt. The devitrification process is similar to that of the Al2O3-SiO2 system phase diagram. When the Al2O3 of the batch is higher than 71.8% of the theoretical composition in mullite, a mullite solid solution with excess Al2O3 dissolved in β-mullite is formed, and the corundum phase appears only when Al2O3>80%. The mineral phase composition of fused mullite is generally mullite crystal and glass phase.

Fused mullite is made of high-purity quartz sand and industrial alumina and is smelted on a super large electric arc furnace. Mullite has white color, very, and the needle-like crystals develop well.

Fused mullite technical data:

| Item | Fused Mullite | Sintered Mullite | |||||||

| FM-1 | FM-2 | M75 | M70-1 | M70-2 | M60-1 | M60-2 | M45-1 | M45-2 | |

| Al2O3 % | 70-77 | 67-74 | 73-78 | 68- 73 | 68- 73 | 57- 62 | 57- 62 | 43- 48 | 43- 48 |

| SiO2 % | 22-29 | 21-28 | – – | – – | – – | – – | – – | – – | – – |

| TiO2 % ≤ | 0.1 | 2 | 0.5 | 0.5 | 3.5 | 0.5 | 2.5 | 1 | 1.5 |

| Fe2O3 ≤ | 0.2 | 0.6 | 0.5 | 0.5 | 1.5 | 0.5 | 1.5 | 0.5 | 1.3 |

| Na2O+K2O ≤ | 0.4 | 0.5 | 0.5 | 0.4 | 0.4 | 0.3 | 0.3 | 0.4 | 0.5 |

| Bulk Density g/cm3 ≥ | 2.9 | 2.9 | 2.9 | 2.85 | 2.75 | 2.65 | 2.65 | 2.55 | 2.55 |

| Apperant porosity % ≤ | 5 | 4 | 3 | 3 | 5 | 5 | 5 | 4 | 4 |

Characteristics of Fused mullite:

1.Fused mullite has low residual carbon, low porosity, low impurity content.

2.Fused mullite has high flexural strength, and soft load.

3.Anti chemical corrosion

4.Fused mullite has Good thermal shock resistant

5.Fused mullite has Low creep rate at high temperature

Fused mullite is made of high-purity quartz sand and industrial alumina and is smelted on a super large electric arc furnace. Mullite has white color, very, and the needle-like crystals develop well.

Advantages of Fused mullite:

1. Easy out of shell.

2. No deformation.

3. No reduced scale.

4. Good brightness , Good finish .

5. Product rate is high.

Fused mullite is suitable for Stainless steel, alloy steel, carbon steel, heat-resistant steel, titanium alloy, nickel alloy, aluminum alloy, cast iron, cast copper complex precision castings and big, medium and small castings, etc.

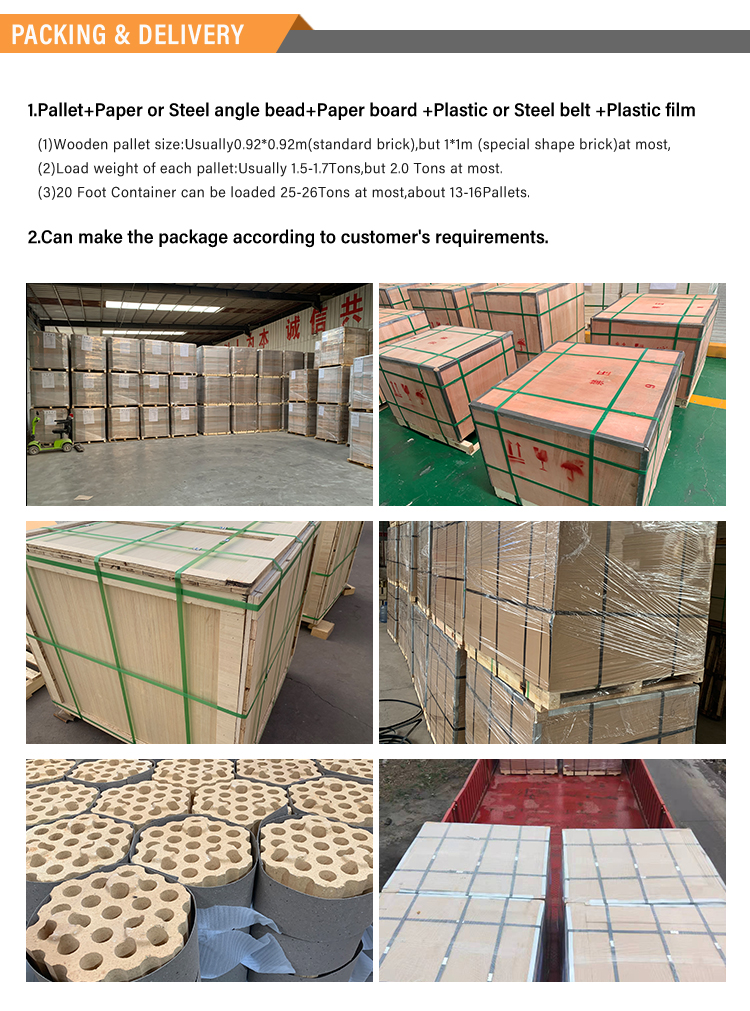

Package and shipping of Fused mullite

Package Informations:

1.Ton bag with 25Kg/ bag.

2.According to customer's requirements.

(1) ton bag, or 25 kg/small bag,then ton bag, as your requirement

(2) 20 Foot Container can be loaded 25Tons,40 Foot Container can be loaded 28Tons.

Fused mullite Shipping

1. FEDEX/DHL/UPS/TNT for samples.

2. By Sea for batch goods.

3. Customers specifying freight forwarders or negotiable shipping methods!

4. Delivery Time:3 days for common shape samples;15 days for special shape samples.Within 30 days for batch goods.

|

|

International Standard CaO and CrO Content Fused Mullite Grain for Mullite Brick Images |