| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Place of Origin : Henan, China

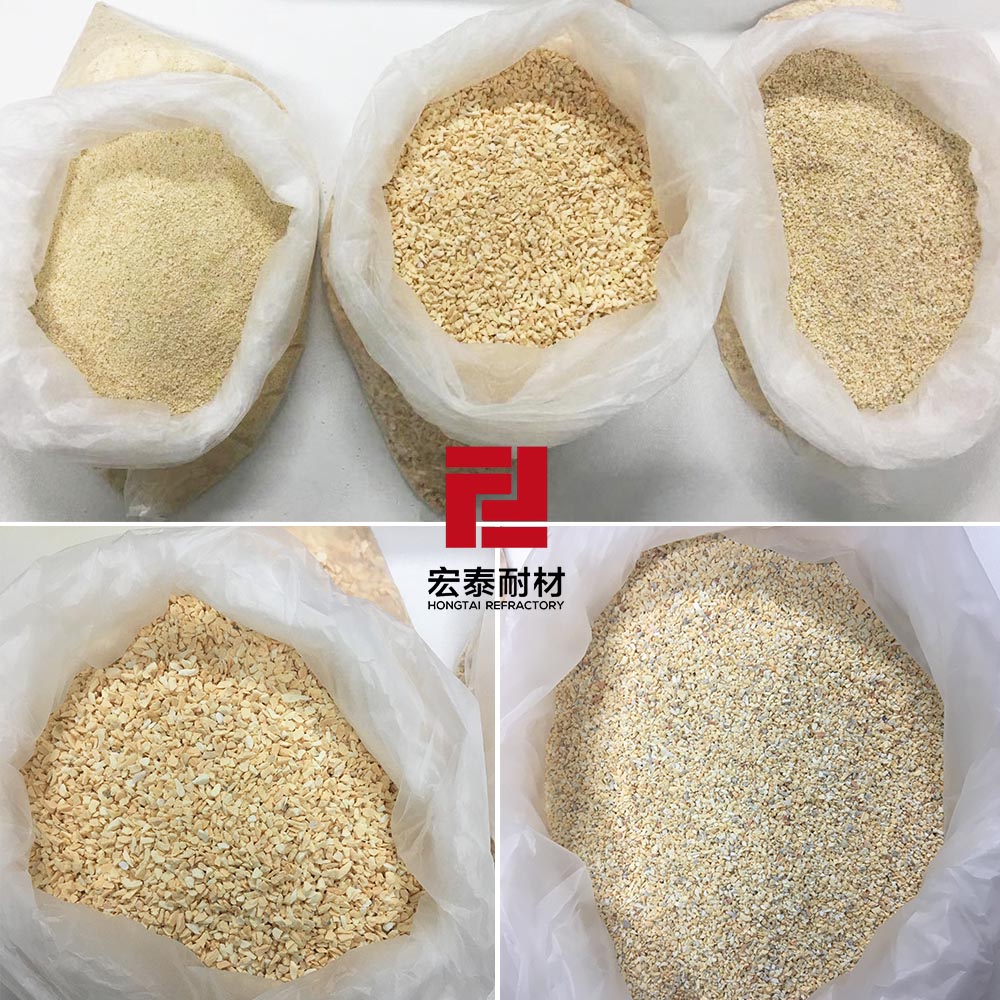

Shape : Powder

Material : Zirconia

SiO2 Content (%) : 30

Al2O3 Content (%) : 0.5

MgO Content (%) : International standard

CaO Content (%) : International standard

Refractoriness (Degree) : Common (1580°< Refractoriness< 1770°)

CrO Content (%) : International standard

SiC Content (%) : International standard

Model Number : GDL

Brand Name : Hongtai

Application : glass furnace

Product name : azs grains

Color : White

Usage : furnace bottom

Bulk density(g/cm3) : 3.45g/cm3

ZrO2 : 60

Fe2O3 : 0.5% Max

Sample : Sample Provided

Certificate : ISO9001

Working temperature : max1650

Packaging Details : Refractory ramming mass and castable is packed with plastic bags, with water-proof cover , and tightened with plastic bandages.

Port : Tianjin, Qingdao, Lianyungang, Shanghai, Ningbo

Supply Ability : 3000 Ton/Tons per Month high alumina refractory brick

MOQ : 2 tons

Price : $500.00 - $800.00/tons

Henan Hongtai refractory brick manufacturer factory price fused cast zircon corundum material AZS grains for glass furnace

AZS grains azs ramming mass

The fused AZS grains azs ramming mass is made by crushing the fused bricks according to a certain particle gradation ratio. It is mainly used as the lining layer (also known as the sealing layer) under the fused cast zirconium corundum pool floor tiles (75~120m). .

The fused AZS grains azs ramming mass has the following characteristics: 1. When the temperature is below 800℃, the expansion will increase regularly according to the coefficient smaller than the expansion coefficient of AZS electrolytic material, which has little relationship with the load. 2. 800℃~1200℃, the exudation of the glass phase will increase to 1200℃, which will produce the following effects: a)In this temperature range, the fused AZS ramming material has good plasticity; b) Fused cast zirconium corundum (ZrO2 32% grade) paving bricks and fused AZS ramming materials both contain about 20% of the glass phase, and they can adhere well to each other. 3. 1200 ℃ ~ 1300 ℃, after 1200 ℃, the glass phase begins to transform into mullite, plasticity weakens, the material begins to change the ceramic body, until the bottom of the pool is sintered into a closed and unbreakable whole.

It can be seen from the above that the key of fused AZS grains azs ramming material is made by crushing original bricks, which contains about 20% glass phase. The presence of the glass phase in the fused AZS ramming compound makes it become a strained material after it exceeds 800℃. The plasticity and adhesion of the material in the temperature range of 800~1300℃ are conducive to the weak displacement of the joints. Keep the bottom airtight, and form a reliable intermediate layer between the fused cast zirconium corundum paving tiles containing the same glass phase, which can effectively prevent the foamed glass from penetrating between the paving tiles and the lining layer and avoid "upward drilling" erosion The bottom life of the pool can be extended.

Henan Hongtai refractory brick manufacturer factory price fused cast zircon corundum material AZS grains for glass furnace

| Item | Behaviors | |||

| AZSR-50V ERSOL 50 | AZSM-06J ERSOL 06 | AZSM-05 ERSOL 05 | ||

| Chemical Composition | Al2O3 | 48 | 48 | 48 |

| ZrO2 | 30 | 30 | 30 | |

| SiO2 | 20 | 20 | 20 | |

| Others | 2 | 2 | 2 | |

| Bulk density g/cm3 | 3.2 | 3.1 | 3.1 | |

| Crystallographic analysis after being sintered at 1300/1500°C | Corundum, zirconium oxide | Corundum, zirconium oxide | Corundum, zirconium oxide | |

| Thermal conductivity | Good | Good | Good | |

| Anti-corrosion property | Excellent at 1300°C | Excellent at 1300°C | Excellent at 1300°C | |

| particle diameter of grain | 0-5mm | 0-0.6mm | 0-0.5mm | |

| Application temperature | Cold/low temperature | Cold/low temperature | Cold/low temperature | |

| Quantity of water | 8-10% (proportion by weight) | 10-12% (proportion by weight) | 10-12% (proportion by weight) | |

| Solidification | Water (ceramic) | Water (ceramic) | Water (ceramic) | |

| Packaging | 25kg/bag | 25kg/bag | 25kg/bag | |

| Quality guarantee period | 12 months | 12 months | 12 months | |

| Used for | Under bottom paving, spreading, Melting end and working area | Under bottom paving, spreading and the place between fused cast brick | Under bottom paving, spreading, and the joint between bricks of two layers that are between the fused cast brick | |

Note: Above mentioned indexes allow few deviation for special demanded products.

Henan Hongtai zirconia ramming mix and fused AZS grains for glass furnace

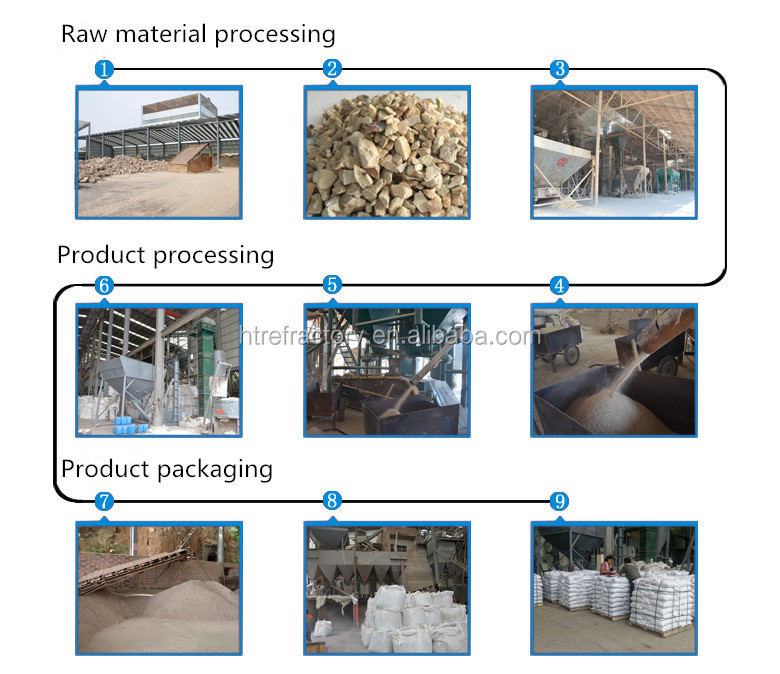

1)Raw material to factory→checkout→burdening→stirring→mixing→taking out the raw material,

2)Crushing→Mixing→Shaping→Drying→Firing→Inspection→Packaging and Shipment.

2.Quality Assurance

2.Quality Assurance

1)Going out the furnace→checkout→packing→qualified product→putting in storage→sale,

2)The process from raw to product are strictly tested by equipment.

1.Inspection and Control of incoming raw materials: according to the chemical content,raw materials are classified into different levels to ensure quality of brick first.

2.Inspection and control of the process: during the production,every brick will be weighed twice strictly to reduce the error of weight .

3.Quality audit by quality management: inspection of product standardization of quality of each product by process control and experimentation, taking corrective measures timely whenever deviations are noted.

4.Before delivery, the inspectors will inspect the size,appearance, physical and chemical properties of brick again in factory.

Henan Hongtai refractory brick manufacturer factory price fused cast zircon corundum material AZS grains for glass furnace

Henan Hongtai Kiln Refractory Co., Ltd. is established in 2005 and located in Xinmi city, 40 kilometers southwest of Zhengzhou city. Rich resources of refractory materials, adequate and qualified fuel in this area, provide unique conditions for refractory production.

Main products are high alumina brick, clay brick, fused zirconium corundum brick, fireproof ball lightweight insulation brick, wear-resistant pouring material, corundum pouring material, low cement high strength pouring material, impermeable material, self-flowing material, plastic material, and various types of refractory materials.

For different industries, the cement industry with anti-flaking high-alumina bricks, alkali resistant bricks, phosphate bricks;Boiler industry USES all kinds of brand wear-resisting brick, corundum brick, mullite brick and other finalizing materials.The company insists on "product quality is the life, enterprise integrity is the foundation", in the fierce market competition, won many users' trust and praise.The products are sold all over the country, as far as Vietnam, India, South Korea, Pakistan, kazakhstan, Mlaysia and other southeast Asian countries and regions.

Henan Hongtai refractory brick manufacturer factory price fused cast zircon corundum material AZS grains for glass furnace

The azs grains azs ramming mass and castable product refers to an amorphous product that is pre-laid at the working temperature/ceramic bonding.

Hongtai has developed a range of integrated products that are a by-product of the electrofusion line and the sintering line. These monolithic products are mainly used in:

- Safety layer for the bottom and the channel

- Cold repair/hot repair special application security layer

- Mud between different refractory materials or brick joints

Henan Hongtai refractory brick manufacturer factory price fused cast zircon corundum material AZS grains for glass furnace

AZS grains Packaging & Shipping

High temperature resistance glass kiln used AZS 33,AZS36,AZS41 ER1681 brick are packaged with fumigated wooden pallet, using paper or non-woven fabrics between layers separated,plastic shrink film protected outside.finally using straps. Or as your requirements.

Delivery:

15-30 days working day for large quantity. The shipment we will arrange as soon as possible. Of course, if it is a custom products, the shipping time will delay.

Sample:

Usually by EMS, DHL, UPS, TNT, FedEx. Anyway you like. Bulk order: Usually by sea.Payment: It can be through T/T, L/C at sight. The specific terms determined according to the quantity of the goods, etc.

Your inquiry related to our product & price will be replied within 24 hours.

Export:

Our products have been exported to many countries: Australia, Chile, USA, Russia, UK, Indonesia, etc., good quality have be approved by our clients.

|

|

Fused Cast Zircon Corundum Material AZS Grains for Glass Furnace ISO9001 Certificate Images |